Simulates fire hazard from glowing elements for electrical products/materials.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

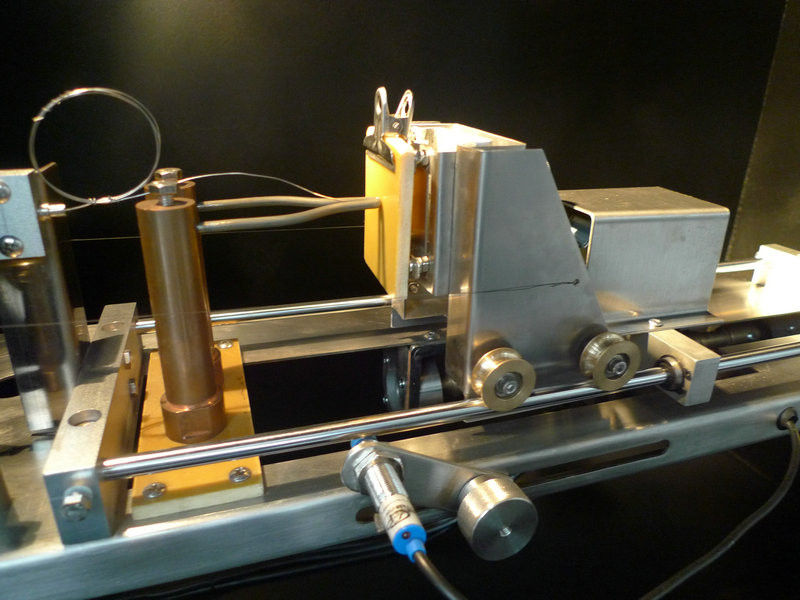

F242 Glow-wire tester, By simulating the thermal stress caused by heat source or ignition source such as hot component or overload resistor in a short period of time, so as to test the flammability and ignitability of circuit component, which is widely used in electronic and electrical, household appliances, household and industrial lighting, electrical insulation materials and so on. And, it can predict the safety during use of circuits, effectively control production and verify product performance.

1.During the use of electrical materials, it may reach excessive temperature and cause fire hazard due to overload, short circuit, poor electrical contact or other fault conditions. The glowing-wire test refers to a simulated an overloaded resistance heat source to apply thermal stress to the sample in a short period of time. The fire risk of the sample is assessed by observing the light-off state of the sample and measuring relevant indicators.

2.After the heating wire of the specified material and shape is heated to the test temperature (550C - 960C) with a large current by the glow-wire test device, so as to confirm that the temperature does not fluctuate obviously within 60 seconds, and the test piece is burned vertically for 30 s at a specified pressure (1.0 N). Measure the ignition hazard of the finished electrical and electronic equipment according to whether the test materials and the mats are light-off or holding time.lt can measure the light-off property, light-off temperature, flammability and flammability index of solid insulating materials and other solid combustible materials.

GB/T 5169.10-2006;EC 60695-2-10-2013:Fire hazard testing for Electrical and electronic products -- Part 10: Glowing-wire/ Hot-wire based test method, Glowing-wire apparatus and common test procedure.

GB/T 5169.11-2006/IEC 60695-2-11-2000: Fire hazard testing for Electrical and electronic products -- Part 11: Glowing-wire/Hot wire basic test method, Glowing-wire flammability test method for finished products.

GB/T 5169.12-2006/IEC 60695-2-12-2000; Electrical and electronic products ,Part 12: Glowing- wire/Hot-wire based test method, Glowing-wire flammability index (GWFI) test method for materials.

GB/T 5169.13-2006/IEC 60695-2-13-2000; Electrical and electronic products ,Part 13: Glowing- wire/Hot wire basic test method, Glowing-wire flammability (GWFI) test method.

UL746A ;

Transparent safety door

The heat-resistant glass observation window allows the test to be observed at any time during the test while keeping the test free from external environmental disturbances.

Automatic heating, illumination, exhaust device

Glowing-wire automatic heating timing, equipped with automatic control of the glowing-wire contact position, precise control, convenient and reliable, and the test device is equipped with lighting and exhaust.

Intelligent touch screen control panel

The microcomputer control system is more efficient and reliable, and the programmable 7-inch color LCD touch screen realizes various functions such as control, detection, calculation and data display.

Stepping motor control - accurate moving speed

The moving speed of the sample is controlled by high-end stepping, which has high precision and long service life. In addition, the test device is equipped with flame ruler, and the flame height can be observed at any time during the test.

Sample rack dis-assembly type design

The sample holder of the test device can be removed for loading and cleaning,and it use physical pressure, which has precise pressure,convenient operation and high efficiency.

It is used in the evaluation of flammability tests and light-off temperature tests for electrical equipment and its components and accessories, as well as solid electrical insulating materials or other solid flammable materials.

It is used for the test of ignition hazard of electronic and electrical products, the evaluation of hot burning performance and the test of high temperature resistance.

It is used to determine the light-off property, light-off temperature, flammability and flammability index of solid insulating materials and other solid combustible materials.

It is used to test flame retardant properties for the insulated enclosure of household appliances, switch panels, printed circuit boards,and insulating materials.

It is applicable to the performance verification of new products, quality control of the production department, and the of material properties for the third-party testing organization, the product performance verification laboratory, and the quality and technical supervisiondepartment, etc.

Enclosure: It is equipped with observation window, inner black fireproof material coating. | special standard ring, horizontal static Temperature sensing delay : 1.7S |

Control screen: Intelligent touch Observation window: transparent | Transformer parameters: 500VA, secondary: 2.5V, 150A Sample load: 1.0N ± 0.1N |

Test speed: 10mm/s ~~25mm/sadjustable | Glowing depth: 0~9mm can be preset |

End of test: buzzer sounds, test piece automatically detaches | which is controlled by high-precision steppermotor. Glowing time: 0~99s |

Test cabinet size: 885mmX580 mm× 1000 mm | Effective volume ofthe test area : ≥0.5m3 |

Pressure limiting depth: 7mm | Exhaust pipe diameter: 100mm |

Testtemperature: room temperature~999C (adjustable) | Physical dimension: 1000mm×650mm×1250mm |

Glowing-wire material: ¢4mm, Ni/Cr (80/20), | Weight: 90kg |

Temperature measuring element: armored K-type thermocouple(¢0.5mm), -200~1300C, precision 1C | Power supply: 220V 50Hz |

YouTube video introduction:https://www.qinsun-tester.com/other/6266.html

Felelősségi nyilatkozat: A fenti tartalom kizárólag az iparági belső személyek közötti hivatkozásra és kommunikációra szolgál, és nem garantálja pontosságát vagy teljességét. A vonatkozó törvények és előírások, valamint a weboldal előírásai szerint a kapcsolódó cikkeket vásárló egységeknek vagy egyéneknek érvényes képesítést és képesítési feltételeket kell megszerezniük.

Vállalati telefon

+86-21-6420 0566

munkaidő

Hétfőtől péntekig

Mobiltelefon:

13816217984

E-mail:

info@qinsun-lab.com