Alkalmazások

1. The presence of hydrogen (the primary gaseous impurity) and various inclusions in aluminum melt significantly increases the risk of casting defects such as pinholes and microshrinkage, severely degrading mechanical properties and internal quality.

2. The hydrogen meter provides a comprehensive assessment of metal purity and aluminum melt cleanliness (gas/slag content).

3. By measuring the density equivalent value of aluminum alloy samples, it quantifies the actual purity (density) of the melt, enabling precise evaluation of how hydrogen and inclusions impact casting quality.

4. This instrument is essential for quality control in aluminum casting operations, offering an effective means to monitor degassing/refining efficiency, melt quality, and smelting process effectiveness.

5. Its user-friendly design makes it ideal for on-site testing in foundries with multiple holding furnaces or aluminum processing facilities (e.g., die casting, extrusion plants).

Service Conditions

The aluminum melt hydrogen meter is designed for use in:

1. Altitudes not exceeding 1,500 meters above sea level

2. Ambient temperatures between 0°C to 90°C

3. Indoor environments free from conductive dust, explosive gases, and corrosive substances that could damage metals or insulation. All electrical components must be protected from physical/chemical deterioration caused by heat, humidity, or environmental factors during normal operation.

Key Features

1. Absolute Pressure Display:

Utilizes a Japanese-imported digital pressure gauge and high-precision American absolute pressure sensor for signal acquisition.

Traditional analog gauges are susceptible to altitude-related pressure variations, whereas our absolute pressure sensor ensures accurate real-time pressure readings regardless of location. This eliminates measurement errors caused by elevation changes, providing consistently reliable data.

- Durable Vacuum Chamber Design:

- Eliminates fragile all-glass bell jars – no risk of chamber damage.

- Constructed from machined aluminum alloy with 10mm high-temperature glass and heat-resistant gaskets, offering shock resistance, rapid heat dissipation, and high-temperature tolerance (up to 100°C).

- Transparent high-temperature glass top enables real-time observation of sample behavior during testing, matching the visibility of traditional glass chambers.

- Mobile Casters for Workstation Flexibility:

- Portable design allows gas content testing at multiple fixed locations (one machine for multiple uses).

- Equipped with four polyurethane casters for smooth, low-vibration movement.

- Front wheels feature locking brakes for secure workstation positioning, preventing unintended movement during operation.

- Sample Cooling System:

- Built-in air cooling system accelerates sample cooling after high-temperature molding, as natural cooling is too slow and water cooling poses safety risks in foundry environments.

- Reduces cooling time, improves testing efficiency, and ensures operational safety in casting facilities.

- High-Temperature Resistant 304 Stainless Steel Worktop:

- Designed for foundry use, the brushed stainless steel surface resists deformation, discoloration, and corrosion from accidental aluminum spills or other contaminants.

- Maintains aesthetic appeal through easy cleaning, preventing equipment degradation and preserving professional appearance.

- Comprehensive Data Output:

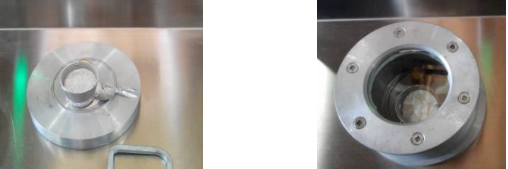

- 7-inch computer monitor for clear test result display.

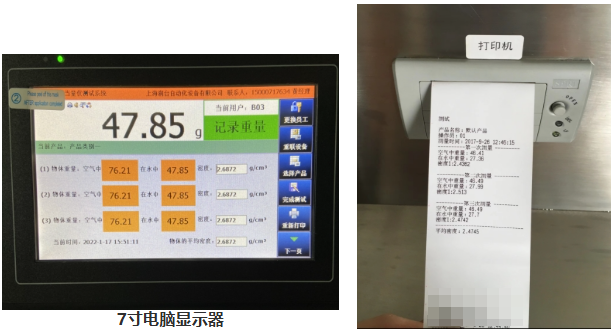

- Optional integrated printer for hardcopy results.

- USB interface supports data export for external analysis or archiving, enabling seamless integration with quality control systems.

- Multi-functional Testing Capabilities:

- Enables reduced-pressure density testing and sample preparation for versatile applications.

- Rapid Analysis:

- Completes aluminum melt quality analysis within 5 minutes under field conditions.

- Reliable and Repeatable Results:

- Integrates multiple analytical methods for accurate melt quality assessment, providing actionable production guidance.

- Magnified Defect Detection:

- Amplifies aluminum melt defects (e.g., porosity, shrinkage) through controlled solidification conditions, enabling precise quality evaluation.

- Quantitative Analysis:

- Eliminates ambiguities of traditional methods (e.g., visual sample inspection) through objective numerical evaluation.

- User-Friendly Operation:

- Requires minimal operator experience – brief training suffices for proper use.

- Built-in Data Management:

- Includes data calculation, storage, and USB export capabilities for traceability and analysis.

- Self-Verification System:

- Automatically detects sample placement errors and prompts correction, with optional data realignment if authorized.

Density Equivalent (DI) Calculation

- Definition:

- DI quantifies aluminum melt quality by comparing densities of samples solidified under normal pressure (ρₐ) and reduced pressure (ρᵦ).

- Formula:

DI=ρaρa−ρβ×100%=(1−ρaρβ)×100% - Pristine aluminum (theoretical) would yield ρₐ = ρᵦ and DI = 0%. Lower DI values indicate superior melt quality.

Instrument Composition

The RT-CQY-1000 Hydrogen Meter comprises two primary systems:

5.1 Sample Preparation System

- Produces normal-pressure and reduced-pressure samples from the same aluminum melt batch.

Components:

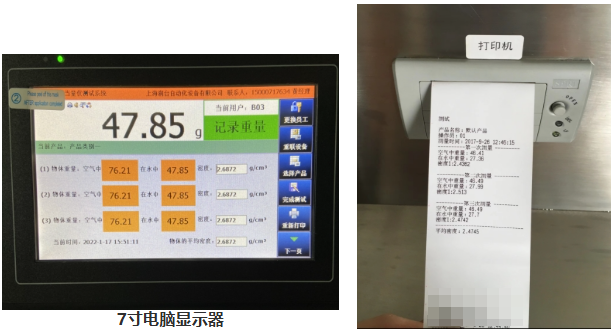

- A. Vacuum System:

- Includes vacuum pump, solenoid valves, chamber, pressure regulator, and digital gauge (imported Japanese sensor).

- Chamber constructed from aluminum alloy with 10mm high-temperature glass and corrosion-resistant seals, eliminating fragile glass components.

- B. Rigid Frame:

- Supports vacuum system components on a durable chassis with four locking casters for mobility.

- C. Electrical Control System:

- Pressure sensor feeds real-time data to a digital display.

- Control panel features start/stop buttons and timing relays for automated vacuum sequencing.

Sample Preparation Process:

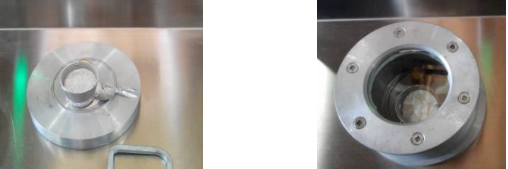

- A. Reduced-Pressure Sample:

- Preheat nickel crucible (with coating).

- Extract ~100g aluminum from melt core.

- Place crucible in vacuum chamber within 15 seconds.

- Pump to preset vacuum (typically 8kPa) for controlled solidification.

- B. Normal-Pressure Sample:

- Use preheated crucible to extract ~100g aluminum from melt core.

- Solidify naturally under ambient conditions with protective cover.

5.2 Data Terminal

Components:

- A. Measurement Module:

- Precision electronic balance, sample holder, and water displacement cup for density analysis.

This system ensures accurate, efficient, and safe aluminum melt quality control through advanced engineering and user-centric design.

5.2.1 Components: divided into data measurement section and data calculation, storage, and printing section.

A、 The data measurement part. Composed of precision electronic balance, sample holder, water cup, etc.

High-precision balance

B、 The data processing part,

It consists of a display screen, printer, transfer port, mouse, and other components.

Technical Specifications

- Tápegység: 220V/50Hz

- Total Instrument Power: <500W

This technical specification sheet outlines the performance parameters of the RT-CQY-1000 Hydrogen Meter, emphasizing its precision, speed, and operational reliability in industrial aluminum melt quality control.

- Ultimate Vacuum Level: 3 kPa (Absolute pressure: 30 mbar; Relative pressure: -0.097 MPa vs. 1 atm)

- Adjustable Vacuum Range: 50–100 mbar

- Vacuum Control Accuracy: ±0.2 kPa

- Sample Preparation Time: <5 minutes

- Time to Reach Ultimate Vacuum: ≤4 seconds

- Maximum Allowable Vacuum Chamber Temperature: 150°C

- Digital Vacuum Pressure Display: Yes (with real-time vacuum duration timer)

- Heat-Resistant Glass Lid: High-strength tempered glass for direct sample observation

- Density Index Measurement:

- Accuracy: <±0.02

- Repeatability: <±0.02

- Electronic Balance Specifications:

- Measurement Range: 500 g

- Display Resolution: 0.01 g

- Repeatability: ±0.001 g

- Response Time: ~2 seconds

- Automated Functions:

- Real-time density and density equivalent calculation

- Instant display of analytical results

- Electronics Enclosure: Sealed and dust-protected housing

| Item No. | Category | Component Name | Specifications & Model | Quantity | Remarks |

|---|

| 1 | Sample Preparation | Vacuum Chamber | 1 set |

|

|

| 2 |

| Vacuum Pump |

| 1 pc |

|

| 3 |

| Pneumatic System | 1 set |

|

|

| 4 |

| Electrical Control | 1 set |

|

|

| 5 | Data Measurement | Precision Balance | 1 unit |

|

|

| 6 |

| Water Cup | 1 pc |

|

|

| 7 | Data Processing | Computer & Printer | 1 set |

|

|

| 8 | Accessories | Thermal Paper | 2 rolls |

|

|

| 9 |

| Nickel Crucible | 4 pcs |

|

|

| 10 |

| Crucible Tongs | 2 pcs |

|

|

| 11 |

| O-Ring Seals | 2 pcs |

|

|

| 12 |

| User Manual | 1 copy |

|

| No. | Név | Brand | Remarks |

|---|

| 1 | Circuit Breaker | Delixi | Domestic Brand |

| 2 | Contactor | Siemens | German Brand |

| 3 | Intermediate Relay | Schneider | French Brand |

| 4 | Switching Power Supply | Schneider | French Brand |

| 5 | Pressure Gauge | SNIMADEN | Japanese Brand |

| 6 | Nyomásérzékelő | Measurement | American Brand |

| 7 | Time Relay | Xinling | Domestic Brand |

| 8 | 7-inch Display | MCGS | Domestic Brand |

| 9 | Printer | Weihuang | Domestic Brand |

| 10 | XZ-1 Vacuum Pump | German Import | German Brand |

| 11 | Density Balance | Shanghai Runtai | Domestic Brand |

Felelősségi nyilatkozat: A fenti tartalom kizárólag az iparági belső személyek közötti hivatkozásra és kommunikációra szolgál, és nem garantálja pontosságát vagy teljességét. A vonatkozó törvények és előírások, valamint a weboldal előírásai szerint a kapcsolódó cikkeket vásárló egységeknek vagy egyéneknek érvényes képesítést és képesítési feltételeket kell megszerezniük.